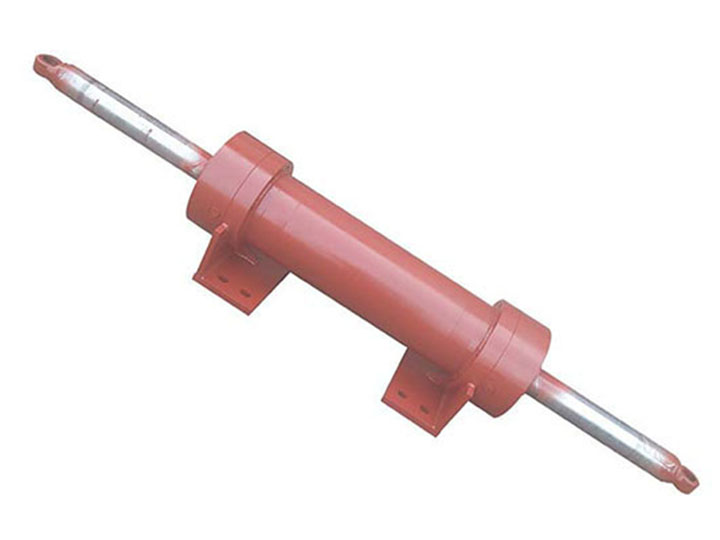

double discharge cylinder(double discharge cylinder,produced by Hengyu Group)double discharge cylinder are widely used ,because of no transmission clearance

(double discharge cylinder,produced by Hengyu Group)

double discharge cylinder are widely used ,because of no transmission clearance,powerful torque,clever hydraulic energy conversion.So our company has designed double discharge cylinder for our customers.

If the double discharge cylinder is sliding or crawling (stop and go), check whether there is any astringency inside the double discharge cylinder. The internal parts of the double discharge cylinder are improperly assembled, the parts are deformed, worn or the shape and position tolerance is excessive, and the action resistance is too large, so that the piston speed of the double discharge cylinder changes with the different stroke position, and there is slip or crawl. Most of the reasons are due to poor assembly quality of parts, surface scars or sintered iron filings, so that the resistance increases, the speed decreases. For example, the piston is different from the piston rod or the piston rod is bent, the double discharge cylinder or the piston rod is offset from the mounting position of the guide rail, and the sealing ring is too tight or too loose. The solution is to repair or adjust, replace damaged parts and remove iron filings. At the same time, check whether the lubrication is good or whether the double discharge cylinder bore processing is out of whack. Because the piston and double discharge cylinder, guide rail and piston rod are relative If the double discharge cylinder is crawling seriously, check whether air has entered the hydraulic system. Air compression or expansion can cause the piston to slip or crawl. The exclusion measures are to check the hydraulic pump, set up a special exhaust device, and quickly operate the exhaust several times in the full stroke. Check the seals at the same time, because the quality of the seals is directly related to slippage or crawling. When the O-ring is used under low pressure, compared with the U-ring, it is easy to slip or crawl because of the higher surface pressure and the larger difference between static and static friction resistance. The surface pressure of the U-shaped sealing ring increases with the increase of pressure, although the sealing effect is correspondingly improved, but the difference between static and static friction resistance is also larger, the internal pressure increases, affecting the rubber elasticity, due to the increase in the contact resistance of the lip, the sealing ring will tip over and the lip elongation, and it is also easy to cause slip or crawling double discharge cylinder weight composition and calculation. The weight of the double discharge cylinder is composed of the double discharge cylinder diameter, the outer diameter and weight of the double discharge cylinder, the rod diameter, and the weight of the accessories, so in calculation, it is to add all these together to get the specific value. However, if there are special circumstances, it may be calculated separately. This work can be carried out by yourself, but it can also be carried out by professionals, so that mistakes can be avoided.

The role of the double discharge cylinder in the mold industry: the double discharge cylinder has a variety of uses in the mold, one is that the core distance is very large, or because of the mechanism of the product, only the double discharge cylinder is reasonable or more cost saving. Let the side core be extracted before opening the mold. Hot runner is mainly based on the product to decide, sometimes customers require the use of hot runner, the price is more expensive, but there are many benefits, you can save raw materials, shorten the molding cycle The double discharge cylinder has an irreplaceable role in the heavy industry production process: it is mainly used in places that need to support heavy objects for a long time, and it can still support heavy objects when the oil pressure is removed, and it is safe and reliable. Can be used underwater, single action, load reversion, nut self-locking to make the load safer, especially in large projects, is easy to operate control and self-locking jack, designed with a safety pressure retaining device, built-in pressure relief valve to prevent overload, to protect the self-locking jack to facilitate safe operation. The connection of the device is connected by high pressure hose and threaded joint, which has the advantages of fast use and overcoming the shortcomings of fast traditional joint oil leakage. It is mainly used for equipment installation and toppling operation in various industries such as electric power, construction, machinery manufacturing, mining, railway bridge, shipbuilding and so on.

The pressure, temperature, medium and speed of different types of seals are not the same, water-ethylene glycol medium (HFC) can not be sealed with polyurethane, it can only use rubber seal; When the double discharge cylinder is running fast, it must be sealed with slip ring, such as Sterseal, Glairing, GD1000K, TDI, etc., when the running speed is slow, Yx, U, V combination seals can be used; Fluorine rubber seal is used in high temperature and high pressure environment; When the running speed is fast, the buffer sleeve and buffer valve must be considered.

When the oil pressure of the double discharge cylinder inlet is too low to reach the specified value, the leakage situation of the relevant oil system should be checked and the leakage should be eliminated; Check the piston and piston rod seal ring for damage, aging, loose and other phenomena; Check whether the hydraulic pump and pressure valve are faulty.

Hydraulic cylinder performance requirements?

Hydraulic cylinder performance requirements: hydraulic cylinder is the hydraulic system to achieve energy transfer, conversion and control of the working medium, in addition, it is also responsible for the lubrication of the system, rust prevention, corrosion prevention and cooling. The performance of hydraulic oil will make the system flexible, accurate and reliable. Hydraulic performance requirements are determined according to the design parameters of the hydraulic system, operating conditions, the structure of the hydraulic pump and the working environment. Appropriate viscosity and good viscosion-temperature performance Viscosity is an important performance indicator of hydraulic pressure, which has an important impact on the smooth operation of the hydraulic system and the friction parts. The low temperature performance of hydraulic oil includes three aspects: low temperature flow, low temperature start-up and low temperature pumping.

Why are the hydraulic cylinders out of sync? The reasons for the unsynchronous operation are as follows: 1, the deviation of the external load of the two cylinders, such as the different resistance and friction of the two cylinders will lead to imbalance. The displacement of the cylinder with low resistance will be larger. 2, the difference in internal friction, such as the difference between the piston and the cylinder of each cylinder, the friction between the piston rod and the seal causes the cylinder to be out of sync. 3. The different resistance of hydraulic oil along the pipeline of the two cylinders causes the cylinder to be out of sync. 4, the deviation of the control original adjustment causes the deviation of the flow to be out of sync, such as the use of an independent throttle valve for each cylinder will appear the difference in the flow of oil in and out of the oil affecting the synchronization of the two cylinders. 5. The cylinder support point of the supported part is initially different.