Release time:2023-11-12 15:28:39 Hits: Current position: Home > News

This article mainly introduces:

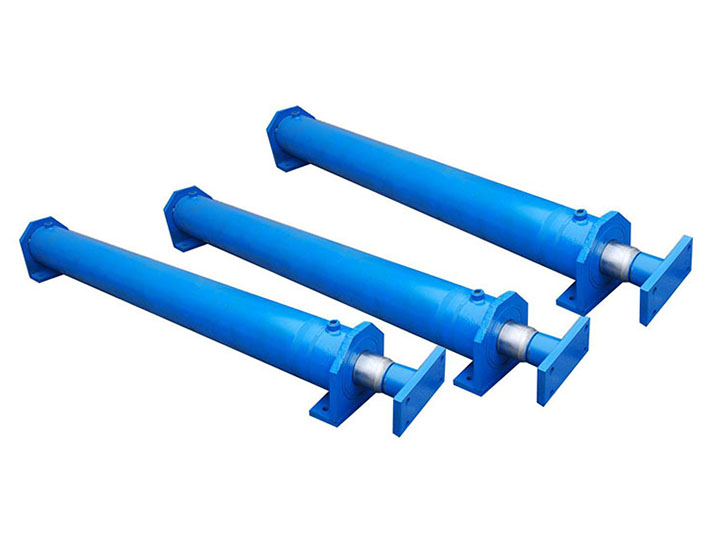

Switzerland hydraulic cylinder,hydraulic jig cylinder manufacturer,hydraulic jig cylinder

(Switzerland hydraulic jig cylinder,produced by Hengyu Hydraulic Cylinder Factory)

hydraulic jig cylinder are widely used in Switzerland,because of excellent fatigue and impact resistance,no need for deceleration device,long service life.So our company has designed hydraulic jig cylinder for customers from Switzerland.

If the hydraulic jig cylinder is sliding or crawling (stop and go), check whether there is any astringency inside the hydraulic jig cylinder. The internal parts of the hydraulic jig cylinder are improperly assembled, the parts are deformed, worn or the shape and position tolerance is excessive, and the action resistance is too large, so that the piston speed of the hydraulic jig cylinder changes with the different stroke position, and there is slip or crawl. Most of the reasons are due to poor assembly quality of parts, surface scars or sintered iron filings, so that the resistance increases, the speed decreases. For example, the piston is different from the piston rod or the piston rod is bent, the hydraulic jig cylinder or the piston rod is offset from the mounting position of the guide rail, and the sealing ring is too tight or too loose. The solution is to repair or adjust, replace damaged parts and remove iron filings. At the same time, check whether the lubrication is good or whether the hydraulic jig cylinder bore processing is out of whack. Because the piston and hydraulic jig cylinder, guide rail and piston rod are relative If the hydraulic jig cylinder is crawling seriously, check whether air has entered the hydraulic system. Air compression or expansion can cause the piston to slip or crawl. The exclusion measures are to check the hydraulic pump, set up a special exhaust device, and quickly operate the exhaust several times in the full stroke. Check the seals at the same time, because the quality of the seals is directly related to slippage or crawling. When the O-ring is used under low pressure, compared with the U-ring, it is easy to slip or crawl because of the higher surface pressure and the larger difference between static and static friction resistance. The surface pressure of the U-shaped sealing ring increases with the increase of pressure, although the sealing effect is correspondingly improved, but the difference between static and static friction resistance is also larger, the internal pressure increases, affecting the rubber elasticity, due to the increase in the contact resistance of the lip, the sealing ring will tip over and the lip elongation, and it is also easy to cause slip or crawling hydraulic jig cylinder weight composition and calculation. The weight of the hydraulic jig cylinder is composed of the hydraulic jig cylinder diameter, the outer diameter and weight of the hydraulic jig cylinder, the rod diameter, and the weight of the accessories, so in calculation, it is to add all these together to get the specific value. However, if there are special circumstances, it may be calculated separately. This work can be carried out by yourself, but it can also be carried out by professionals, so that mistakes can be avoided.

The hydraulic jig cylinder body is commonly made of No. 20, 35, 45 seamless steel pipe, and the steel pipe is honed or rolled to achieve the roughness requirement within 0.4μm. The low pressure hydraulic jig cylinder can use 20 steel pipe, and the high pressure hydraulic jig cylinder can use 45 steel pipe.

The body of the hydraulic jig cylinder on the processing process requirements: the body of the hydraulic jig cylinder is an important and essential part of the hydraulic jig cylinder, because it has an irreplaceable role. The processing requirements for this part are very high, requiring that the surface roughness of the hydraulic jig cylinder after processing should reach 0.4-0.8um, and the coaxiality and wear resistance requirements are also very high.

When the hydraulic jig cylinder thrust is insufficient, check the hydraulic circuit for leaks. Including leakage of valves and hydraulic lines. The inspection method is to check and eliminate the leakage of the hydraulic connection line by manipulating the reversing valve. Also consider the relief valve. If the relief valve enters the dirt and jams the spool, so that the relief valve is normally open, the hydraulic oil will flow directly back to the tank through the relief valve bypass, resulting in no oil in the hydraulic jig cylinder. If the load is too large, although the regulating pressure of the relief valve has reached the maximum rating, the hydraulic jig cylinder still cannot get the thrust required for continuous action without action. If the regulating pressure is low, the pressure is insufficient to achieve the required vertebra force, which is manifested as insufficient thrust. Check and adjust the relief valve at this time.

The hydraulic cylinder is slow when moving forward and faster when moving back.

If the cylinder is single, it is slow when it is moving forward without the rod cavity, and fast when it is shrinking.

How to calculate the inner diameter of the hydraulic cylinder?

These two parameters need the following information to decide: 1, pump displacement, speed (to get the actual output flow of the pump) 2, three and time requirements (lift time, drop time takes a few seconds) and then view the close cylinder series according to the results. Select the right cylinder.